Thus far, all the prevention methods have focused on the physical roots of ESD. We did not explore some of the human or systemic roots that are also accountable for ESD. In this section, we will develop a logic tree designed to address a critical failure occurring in a plant. This will be used as an example of the logic tree, which can be developed when investigating the root causes of ESD.

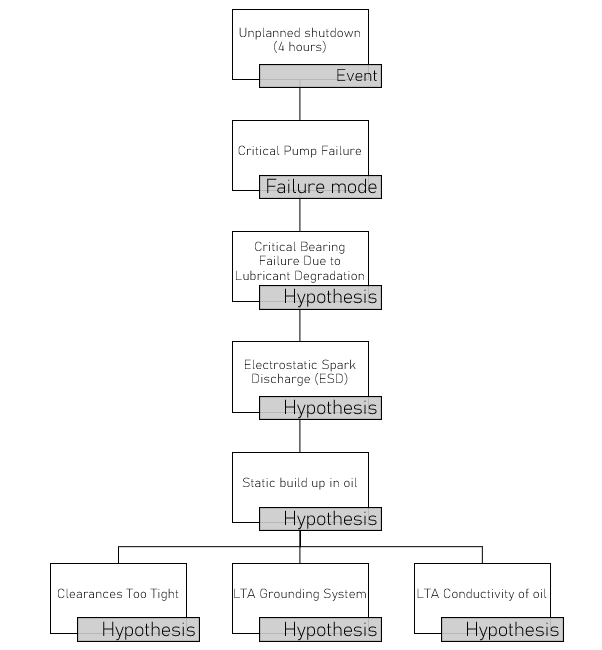

Let’s start with the top of the logic tree, where we define the event or the reason we care. In this situation, it is an unplanned shutdown for 4 hours. An unplanned shutdown will impact the plant’s production, which is why we care about conducting this investigation.

We will assume that the failure mode occurred on one of the critical pumps, and we are investigating how that failure could have happened. Note, we did not ask the question “Why?” because it can be misleading to an opinion, and we are trying to stay as factual as possible.

A disciplined root cause analysis doesn’t start with ‘why’ – it starts with evidence. Each degradation mechanism tells its own story, and Electrostatic Spark Discharge is just one of them.

For this investigation, we will investigate the hypothesis of a critical bearing failing due to lubricant degradation. Since we are focused on ESD for this article, we will have only one hypothesis regarding the degradation mode being ESD. However, in the real world, if this logic tree were being developed, we would be investigating the six various lubricant degradation mechanisms: oxidation, thermal degradation, microdieseling, ESD, additive depletion, and contamination.

As shown in Figure 1, at the top of the logic tree, we start by placing our hypotheses on the tree, and then using evidence/facts, we can rule them out afterwards. This is a critical step as the investigation should be able to stand on its own in the court of law (even if it may not reach that point). The next hypothesis is the buildup of static in the oil. There are three possible ways for this to occur;

- Clearances too tight (as discussed earlier, this can lead to molecular friction, which can induce static)

- Less than adequate grounding system (if a proper grounding system doesn’t exist, then there isn’t an option for the static to dissipate)

- Less than adequate conductivity of the oil (if the conductivity of the oil is too low, then the charge can build up and cause it to be dissipated along the system, such as the filters)

Now, we need to investigate each of the three main hypotheses stated and find out the root causes for them.

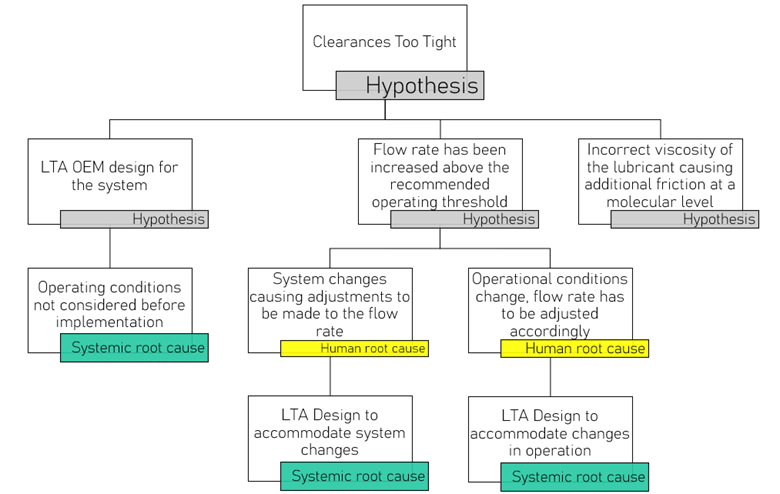

Let’s begin with the Clearances being too tight hypothesis.

For this hypothesis, we will ask the question, “How can clearances be too tight?”. In this case (and we will have to keep it general and in broad buckets, so we can drill down into these later and eliminate as necessary), there are three possible reasons:

- The OEM could have designed the system such that it was less than adequate (LTA)

- The flow rate could have been increased above the recommended threshold

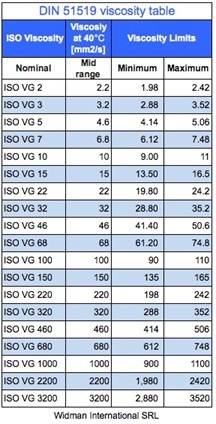

- Incorrect viscosity of the lubricant could cause additional friction (we will dive into this one later).

We will develop the other two hypotheses in Figure 2.

If we further investigate where the OEM did not design the system effectively, we can determine that the operating conditions were probably not adequately considered before implementation. This is a systemic root cause and one that needs to be addressed with the OEM.

On the other hand, if we investigated the flow rate, there could be two main reasons for the adjustment. One could be because of system changes, which forced adjustments to the flow rate. Since a decision was made here, it is a human root cause. Someone decided to change the flow rate based on the variables involved. However, if we investigate why these changes were made (once a human is involved, the question moves from how to why), we can determine that the system was not designed to accommodate these changes. This is a systemic root.

Similarly, if the operational conditions change (such as when a higher output is required, which is different from system changes), then the flow rate must be adjusted. Again, a decision must be made here, and a human is involved. Then we ask the question, “Why?”. In this case, we have the same systemic root, and the design is inadequate to accommodate the necessary changes.

For this part of the tree, we have found some human root causes where decisions were made, as well as systemic root causes. Both need to be addressed when we perform the final root cause analysis. For the human root causes, we can think about the procedures that guided them to make those decisions (if they existed) and amend these accordingly.

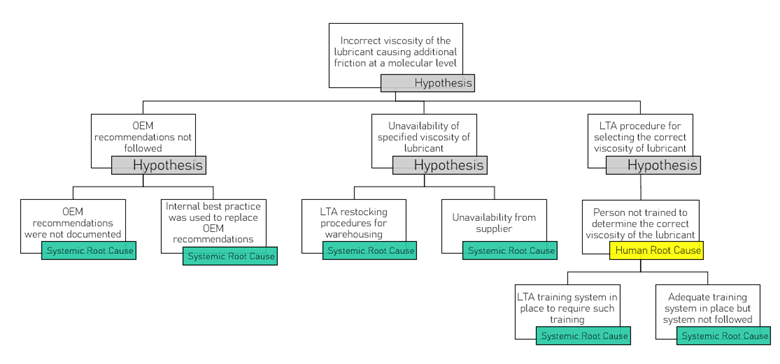

On to the next hypothesis, which we have yet to investigate (still under the clearances being too tight), the incorrect viscosity of the lubricant, which is shown in Figure 3. There are a couple of ways in which this can happen:

- OEM recommendations were not followed

- There was an unavailability of the specified viscosity of the lubricant

- There was a less-than-adequate procedure for selecting the correct viscosity of lubricant

If we investigate why the OEM recommendations were not followed, we can find two main reasons. Either they were not documented and therefore could not be followed, or the internal best practice was used instead to replace the OEM recommendations. In both cases, these would be systemic root causes, and we should investigate why these were not documented or why they were replaced.

When investigating the unavailability of the specified viscosity of the lubricant, we can find two main causes. Either there was an issue with the restocking of this lubricant at the warehouse due to their forecasting, or appropriate checks were not carried out. This is a systemic root cause that should be investigated further.

Another hypothesis could be that the specified lubricant was unavailable from the supplier. This is another systemic root cause and should be addressed with the supplier to ensure it is resolved in the future.

When lubricant viscosity errors trace back to missing stock or missing training, the problem isn’t the person or the product – it’s the system that allowed both to fail.

On the other hand, if we examine the procedure for selecting the correct viscosity of the lubricant, we identify a human root cause, as someone would have made the decision on which viscosity to use. But in this case, we need to investigate why the person was not trained to determine this value.

There are two main reasons why a person does not receive training: either it doesn’t exist, or it was not followed. In both cases, these are systemic roots that need to be further investigated and addressed.

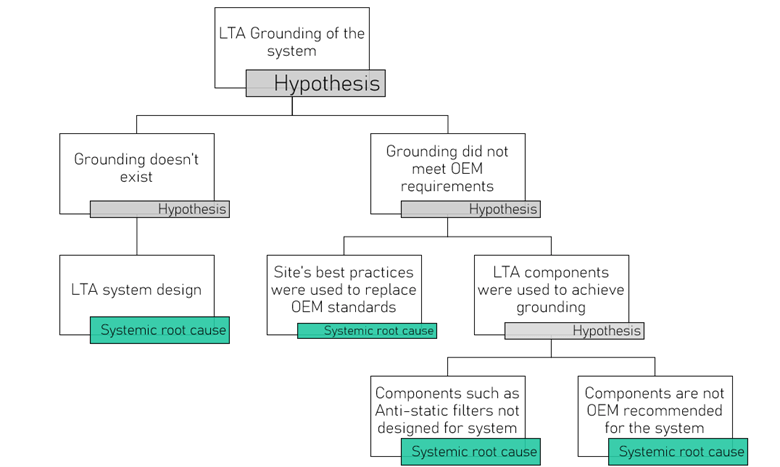

Now, we will investigate the next major hypothesis, “LTA grounding of the system” in Figure 4.

When investigating the grounding of a system, we can identify two major classes: either it doesn’t exist, or it didn’t meet the requirements. If grounding did not exist, then this is an inadequate system design and therefore a systemic root cause. On the other hand, if the grounding did not meet the OEM requirements, we need to determine how this was possible.

There are two possibilities: the site’s best practices were used to replace the OEM standards, which is something we often see, especially if these requirements have worked in the past. This is a systemic root cause that should be investigated. Or there were fewer than adequate components to achieve grounding.

In this case, we can have components that are not designed for the system (do not meet the system’s requirements) or components that were not OEM-recommended and are being used (such as aftermarket products that do not meet the necessary specifications).

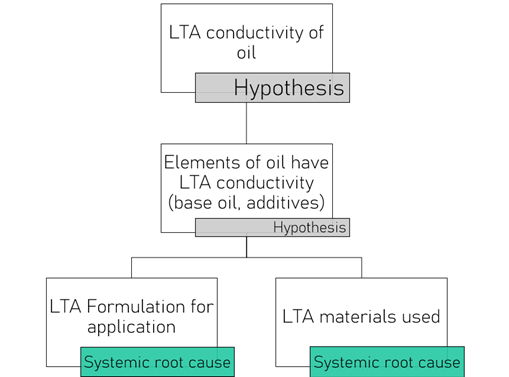

Finally, on to the last major hypothesis, “LTA conductivity of the oil,” as shown in Figure 5.

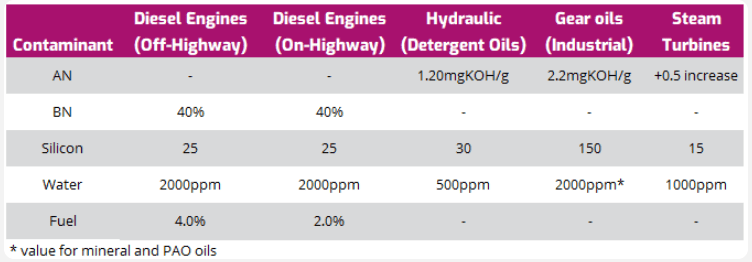

As noted earlier, if an oil has a conductivity of more than 100pS/m, it will be able to dissipate any accumulated charge easily. However, if it falls below this value, the charge will be dissipated in the system at the earliest opportunity.

How can oil have less than adequate conductivity? Perhaps the elements of the oil have a less-than-adequate conductivity. If that is the case, then there can be two plausible reasons for this. Either the formulation was not appropriately designed, or the materials (base oils, additives) were not of a particular standard. Both causes are systemic root causes and should be investigated further to determine if anything can be done to correct these.

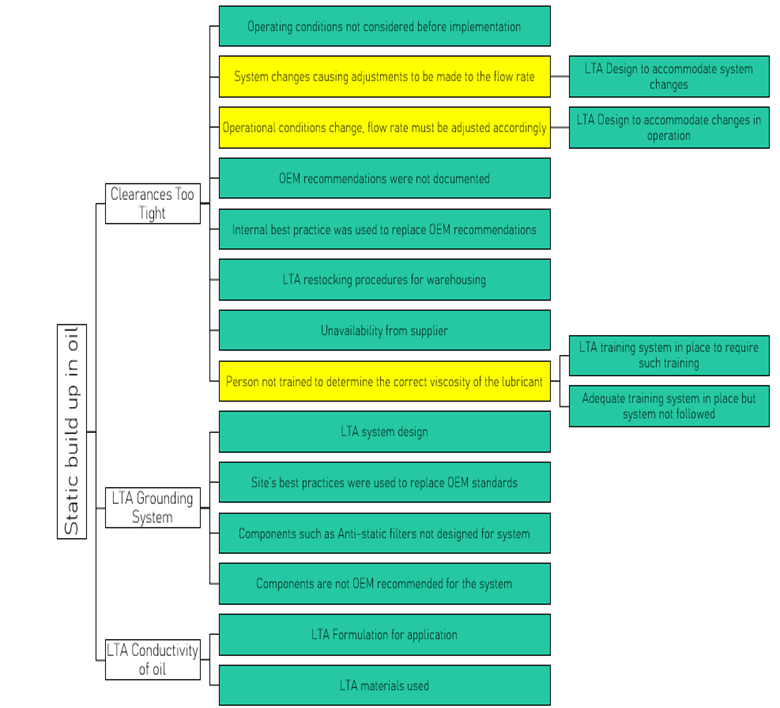

If we were to summarize a list of the root causes, we would see that many are systemic, while a few are human, as shown in Figure 6.

This further reiterates the need to develop a comprehensive logic tree when investigating any failure, as many root causes are not physical or surface-level. If these are not adequately addressed, the failure mode will recur in the future. The entire logic tree can be found here under additional support material, along with logic trees for other degradation mechanisms.

References

Mathura, S. (2020). Lubrication Degradation Mechanisms: A Complete Guide. Boca Raton: CRC Press.

Mathura, S., & Latino, R. (2021). Lubrication Degradation: Getting into the Root Causes. Boca Raton: CRC Press.

Find out more in the full article, "Root Causes of Electrostatic Spark Discharge in Modern Lubrication Systems" featured in Precision Lubrication Magazine by Sanya Mathura, CEO & Founder of Strategic Reliability Solutions Ltd.