Strategic Reliability Solutions Ltd is an Authorized Mobius Institute Training Partner.

Strategic Reliability Solutions Ltd is also an Authorized Mobius Institute Examination Center.

On Demand or Instructor led?

Instructor Led 2024

Field Lubrication (CAT I)

Learn to be a confident and effective Field Lubricant Analyst - demonstrating proven knowledge of industry methods for selecting, storing, filtering, and testing lubricants to boost reliability to generate lasting results in machine availability and overall reliability.

With the use of advanced 3D animations and interactive simulations, we have strived to make everything easy to understand. We will help you understand why field lubrication is important. You will learn the fundamentals of lubrication, and you will learn how to implement the best practices of plant lubrication. Once you complete the training, you can take the exam with confidence, and become certified to ISO 18436-4 Category I via the internationally respected Mobius Institute Board of Certification [MIBoC]. The MIBoC certification is accredited to ISO/IEC 17024, it is the only accredited certification in the world.

This course targets in-plant technicians who perform daily lubrication tasks, such as oil changes, top-ups, greasing bearings, lubricant receiving and dispensing, and lubricant storage and handling. Certified practitioners have demonstrated a working knowledge of applying the best lubrication practices and products. With this certification, you can move away from outdated methods of vague, non-specific lubrication procedures and job plans, and assist with implementing an effective lubrication program in any industrial workplace. Individuals with this certification have proven their knowledge of industry methods for selecting, storing, filtering, and testing lubricants to boost reliability and generate lasting results in machine availability and overall reliability. They also understand oil analysis, which enables them to align their efforts with those of maintenance professionals or oil analysis experts.

This course is intended for the Field Lubrication Analysts who will:

- Manage lubricant delivery, storage, and dispensing.

- Manage a route for machinery re-lubrication and/or inspection.

- Properly change and/or top up the oil in mechanical equipment found in common industrial sites.

- Use simple techniques to select lubricants with the proper base oil and additive system for machines commonly found in industrial settings.

- Use simple techniques to select grease application methods (including automated delivery) that are least intrusive and most effective for machines commonly found in industrial settings

- Use simple techniques to estimate regrease volumes and intervals for machines commonly operated in industrial settings.

- Properly maintain automatic lubrication systems (autogrease, mist systems, etc.).

- Employ basic oil analysis techniques to identify and troubleshoot abnormal lubricant degradation conditions and use simple techniques to adjust the lubricant specification accordingly.

Vibration Analysis (CAT I-III)

An organization with skilled condition monitoring technicians and analysts experiences lower maintenance costs and higher plant reliability. Condition monitoring allows us to detect the onset of failure and detect when the conditions exist that will cause future failures. Coupled with an effective planning and scheduling process, maintenance costs and production downtime can be dramatically reduced.

Rotating machinery, electrical equipment, and practically every other type of equipment you may operate in your plant provide an indication when failure is initiated, for example, when the bearing has the smallest crack forming. While it is necessary to understand how equipment fails, as a general comment, we can achieve anywhere from weeks, months, and even years of warning before failure occurs. That enables us to establish a corrective maintenance plan and schedule the work at the optimal time in order to reduce spare parts holding costs, the time required to perform the corrective maintenance, and the impact on production. Avoiding catastrophic failure obviously reduces the safety and environmental risks, and the possibility of secondary damage. Proper planning increases the quality of the work performed and reduces safety risks for the person performing the work.

Mobius Institute™, and its worldwide authorized partners (one of which is SRSL), provide training that equips technicians, analysts, and CBM leaders with the necessary skills so they can competently and confidently perform their critical roles.

Understanding how the equipment works, how they fail, how the symptoms of failure change over time, and how to correctly take the required measurements, requires detailed knowledge of the equipment and the instrumentation. Mobius Institute takes pride in the fact that we are recognized as the leaders in this form of training. We provide simulations that explain how the machinery and instrumentation work, and animations that enable you to visualize exactly what is going on.

No guesswork, no trying to remember complex concepts and techniques, we educate you so that you understand. It’s only when you understand that you can solve problems.

VIBRATION ANALYSIS CATEGORY I

This is the place to start your vibration analysis career. You will learn all of the essentials so that you can contribute to the vibration analysis program:

- An introduction to condition monitoring and reliability improvement

- The fundamentals of vibration

- How to collect quality data

- An introduction to vibration analysis and common fault conditions

After this course, vibration analysis will make much more sense. You will learn how to do a good job and why it is so important that you do a good job.

The training and accredited certification follow ISO 18436-2 and ISO/IEC 17024.

VIBRATION ANALYSIS CATEGORY II

This course will prepare you to be a real vibration analyst. You will learn:

- Vibration Measurement basics: sensors, mounting, locations, and collecting quality data

- Signal processing basics: sampling, windowing, averaging, and how to set up the data collected correctly

- Equipment fault conditions: unbalance, misalignment, bearings, resonance, and many more

- Vibration analysis techniques: spectral analysis, phase analysis, time waveform analysis

And you will learn many more tips, tricks, and concepts to help you succeed as a vibration analyst. The training and accredited certification follow ISO 18436-2 and ISO/IEC 17024.

VIBRATION ANALYSIS CATEGORY III

This course is for the leader of the vibration analysis program and the person who wants to be the vibration specialist. On this course you will learn:

- Advanced signal processing

- How to diagnose the widest range of fault conditions

- How to utilize all of the vibration data types

- Resonance, dynamics, modal, and ODS

- How to manage a program and lead the team

Every Vibration program should have a Category III vibration analyst leading the program. This is your chance to be the leader. The training and accredited certification follow ISO 18436-2 and ISO/IEC 17024.

Program Implementation via ARP®

To enjoy a truly successful reliability improvement initiative, you need both depth and breadth of knowledge. The leader of the initiative must have a clear view of the entire scope of the initiative, with a detailed understanding of the business proposition, the culture change process, and the individual steps required to implement the strategy.

The reliability engineer must have a depth of knowledge in reliability analysis, maintenance strategy, and best practice, plus condition monitoring (and other topics). And they both must be surrounded by a workforce of people who are engaged and enthusiastic about the initiative.

The Asset Reliability Practitioner [ARP] training and accredited certification program provides the knowledge, qualifications, and growth path to enable a program to be run successfully.

While the following training/certification programs are not solely focused on condition monitoring, in order to implement a successful condition-based maintenance program there is a great deal to know, and the specific condition monitoring technical programs, listed above, do not cover these topics in adequate detail.

The following ARP training program will greatly benefit your condition monitoring program.

ARP-A “RELIABILITY ADVOCATE”

The ARP-A “Reliability Advocate” program will give you the big picture of how condition-based maintenance fits into a reliability and performance improvement initiative.

Improving the reliability of physical assets takes far more than just monitoring their condition, improving lubrication practices, and making some improvements to the maintenance department. To have a truly successful program you must understand how to add value to the organization and thus gain senior management support.

You must have the support of the entire organization, not just a small group of evangelistic condition monitoring and reliability experts.

You must have a coordinated effort between maintenance, operations/ production, engineering, finance, and the reliability group – no more silos.

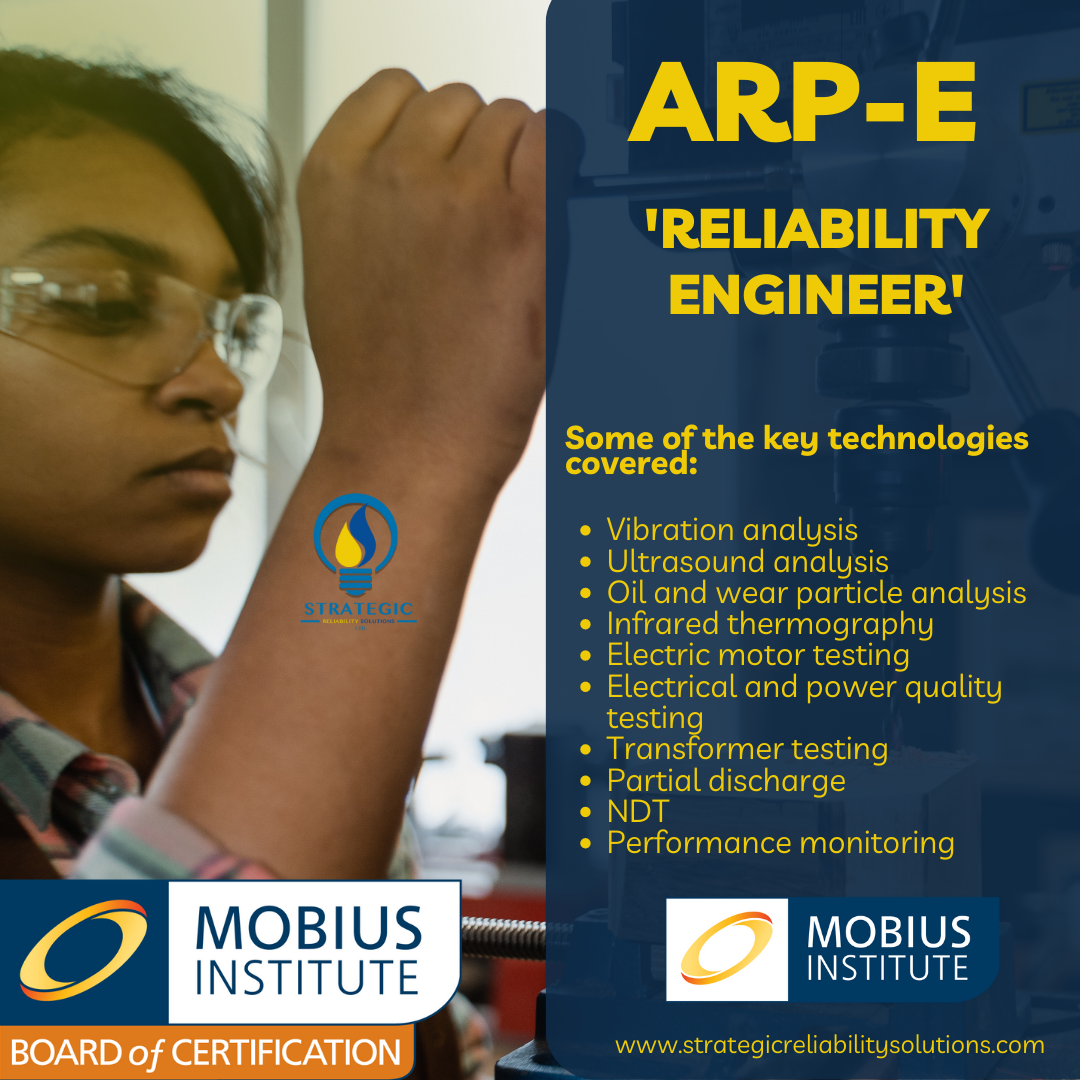

ARP-E “RELIABILITY ENGINEER”

The reliability engineer must be tremendously versatile. They must understand a broad range of technical subjects and be capable of applying them all.

If you are up for the challenge, the Asset Reliability Practitioner [ARP-E] “Reliability Engineer” course is just what you need. You will master everything from defect elimination, asset strategy development with RCM, PMO, and FMEA, planning and scheduling, spares and materials management, condition monitoring, precision maintenance practices, reliability data analysis, criticality and Pareto analysis, root cause analysis and FRACAS, lubrication and asset care, and other topics. There is a lot to learn, but to be a successful reliability engineer, you must learn it all.

Ultrasound Analysis (CAT I)

Ultrasound personnel certified to Category I will have a good understanding of the fundamentals of ultrasound. They are able to apply a specific ultrasound measurement technique, set up and operate ultrasound equipment for safe data collection, and verify the integrity of collected data. They are also able to perform basic fault detection, severity assessment and diagnosis in accordance with established procedures. Additionally, they can maintain a database of results and trends, verify the sensitivity of measurement instruments, evaluate test results and prevent or control factors that results in the acquisition of poor quality data.

Infrared Thermography (CAT I)

This course will prepare you for life as an infrared thermographer. You will learn the fundamentals of infrared energy and the camera, and you will learn about the most common applications.

With the assistance of the Mobius Institute interactive simulations, 3D animations, and a wealth of case studies, you will not be required to have a great memory to learn all of the facts and concepts, instead you will understand the ‘science’ of infrared thermography, you will understand how the camera functions (and thus how to collect good data the first time), and you will learn about the mechanical and electrical failure modes of plant equipment so that you can accurately and confidently detect and diagnose a wide range of fault conditions. You will come away from the course with the knowledge and confidence to be successful as an infrared thermographer.

Precision Maintenance Skills Training

A properly aligned, balanced, and lubricated machine, with correctly tightened fasteners, will deliver maximum reliability. We can help you achieve the skills, awareness, desire, and procedures to ensure the precision becomes standard practice.

Precision Shaft Alignment

Precision-aligned machines run more smoothly and suffer fewer failures - plus they consume less energy. Precision alignment must be part of your reliability improvement strategy. Precision Shaft Alignment makes it easier to gain knowledge, confidence, and competence. Precision Shaft Alignment provides step-by-step training, one slide at a time. The narrations add up to four hours and 39 minutes, but it will take longer to complete the training. Quizzes on each topic area are also included in the training.

Topics include:

- An overview of precision alignment

- A detailed introduction to alignment including the reliability benefits

- The basics of dial-indicator calculations

- Rim-and-face and reverse-dial dial-indicator alignment overview

- Pre-alignment checks

- Soft foot detection and correction

- The rim-and-face method in detail

- The reverse-dial method in detail

- Laser alignment methods in detail

- Moving the machine (and how to deal with the bolt bound and base bound situations)

- Dealing with dynamic and thermal growth

- Machine train alignment

While you can skip the dial indicator training, most experienced alignment practitioners have found that understanding dial indicator alignment has helped them achieve much better results with laser alignment. They find it helps them understand exactly what the laser alignment systems are doing.

Precision Field Balancing

Precision-balanced machines run more smoothly and suffer fewer failures - plus they consume less energy. Precision balancing must be part of your reliability improvement strategy. Precision Field Balancing makes it easier to gain knowledge, confidence, and competence.

Course Agenda:

- Introduction

- What is unbalance

- What causes machines to be out of balance

- Understanding phase

- Phase conventions

- Advanced phase

- Understanding vectors

- Balancing theory

- Different types of unbalance

- Diagnosing unbalance

- Confusing unbalance with other fault conditions

- Preparing for the balance job

- Single plane balancing

- Single plane vector balancing

- Two plane balancing

- Static-couple balancing

- Balancing overhung rotors

- Four run no phase balancing

- Trial weight selection

- Splitting and combining weights

- What can go wrong – and how to recover

- Tolerances and quality and the ISO standards

- Tolerances and quality and the API MIL standards

- Conclusion