What is ICML 55?

ICML 55 is revolutionizing the lubrication industry! It is so exciting to be around at this time when it has started its implementation. For those who aren’t aware of ICML 55, here are a couple of notes on it.

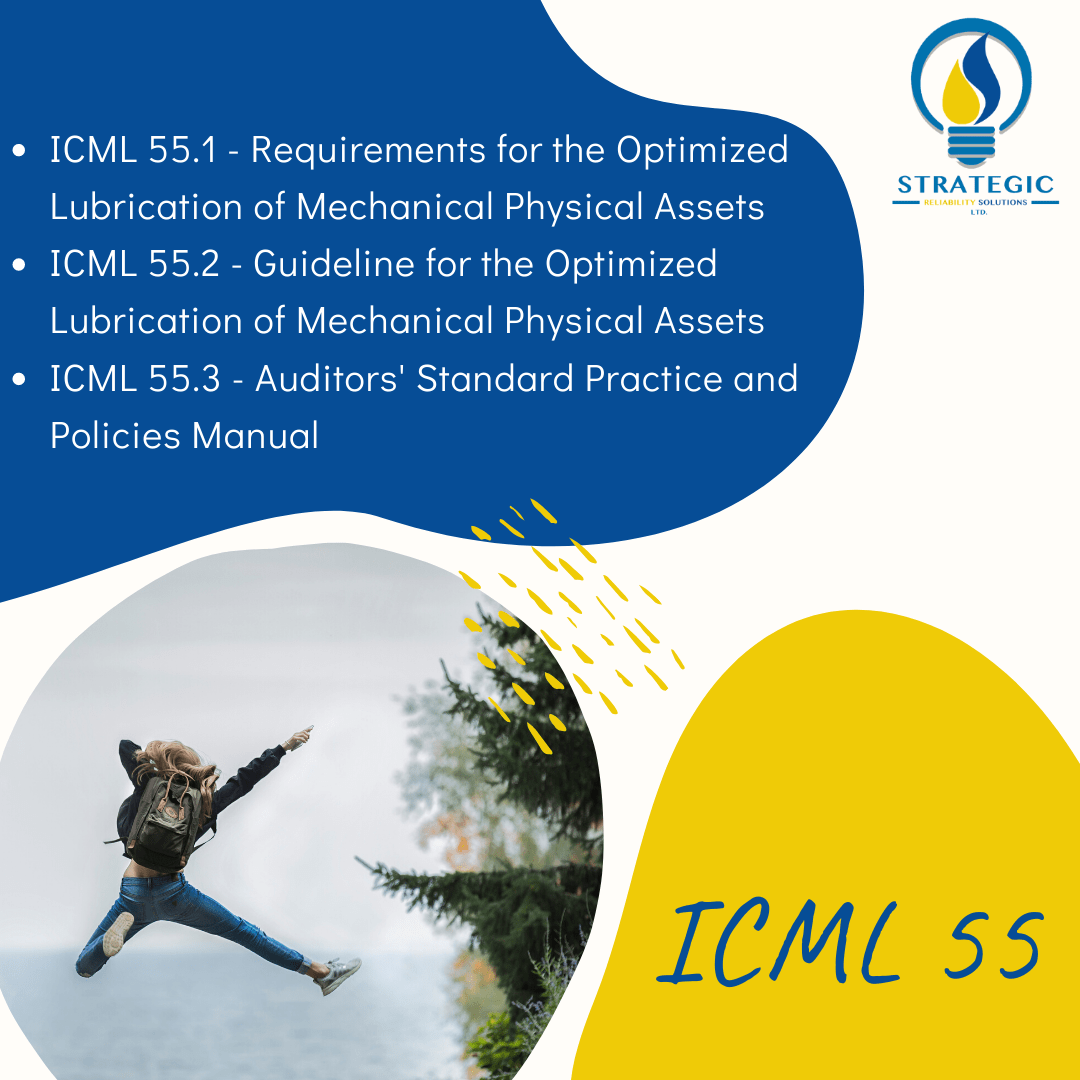

ICML 55 was born out of ISO 55000 which speaks to Asset Management. From this standard, 3 standards were developed to guide the lubrication industry since no previous standards existed within the lubrication industry.

- ICML 55.1 - Requirements for the Optimized Lubrication of Mechanical Physical Assets

- ICML 55.2 - Guideline for the Optimized Lubrication of Mechanical Physical Assets

- ICML 55.3 - Auditors' Standard Practice and Policies Manual

ICML 55.1 has already been completed, while 55.2 should be done at the end of this year and 55.3 scheduled for 2020.

These are exciting times!

Here’s the official press release:

While ICML 55.1 was only launched in April of this year (2019), it is a standard that the lubrication industry has been in need of for several years. It addresses the “Requirements for the Optimized Lubrication of Mechanical Physical Assets”.

What exactly are the assets covered? Here they are:

- Rotating & Reciprocating Machines, Powertrains, Hydraulic Systems and lubricated subcomponents

- Assets with lubricants that reduce friction, wear, corrosion, heat generation or facilitate transfer of energy

- Finished products from API categories I-V

- Non Machinery support assets (Personnel, policies, procedures, storage facilities and management)

There are also fluids and assets which are NOT covered:

- Fuels, coolants, metal-working fluids, pastes, fogging agents, preservative fluids, coating materials, heat-transfer fluids, brake fluids, cosmetic lubricants

- Solid lubricants (e.g., powders and surface treatments used as coating rather than to reduce friction between surfaces in motion)

- Additives independent of the finished lubricant

- Electrical transformer oils and anti-seize compounds

- Fluids and materials derived from a petroleum or petroleum-like base

- Fluids that do not serve a lubrication function

ICML 55.1 speaks to the “Requirements for the Optimized Lubrication of Mechanical Physical Assets” it also describes and defines 12 interrelated areas that can be incorporated in a lubrication program. This has never been officially documented before, nor has any standard been published as a guideline for lubrication programs.

The 12 areas are outlined below:

- SKILLS: Job Task, Training, and Competency

- MACHINE: Machine Lubrication and Condition Monitoring Readiness

- LUBRICANT: Lubricant System Design and Selection

- LUBRICATION: Planned and Corrective Maintenance Tasks

- TOOLS: Lubrication Support Facilities and Tools

- INSPECTION: Machine and Lubricant Inspection

- LUBRICANT ANALYSIS: Condition Monitoring and Lubrication Analysis

- TROUBLESHOOT: Fault/Failure Troubleshooting and RCA

- WASTE: Lubricant Waste Handling and Management

- ENERGY: Energy Conservation and Environmental Impact

- RECLAIM: Oil Reclamation and System Decontamination

- MANAGEMENT: Program Management and Metrics

As per ICML's website, here's a list of people that the new standard can benefit:

Photo Credit: https://info.lubecouncil.org/icml-55-standards/

Check out the ICML 55 standards today and apply it to your organization!