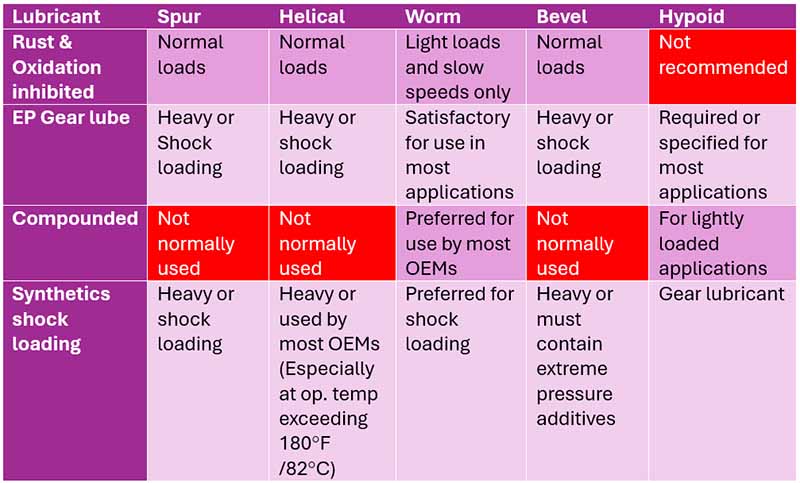

From the information covered thus far, we can appreciate that gear oils need to accommodate many changes to their environment. A few characteristics stand out when looking at industrial gear oils (Mang, Bobzin, & Bartels, Industrial Tribology—Tribosystems, Friction, Wear and Surface Engineering, Lubrication, 2011).

These include viscosity-temperature, Fluid Shear Stability, Corrosion and Rust Protection, Oxidation Stability, Demulsibility and Water Separation, Air release, Paint Compatibility, Seal Compatibility, Foaming, Environmental, and Skin Compatibility.

Depending on where you are in the world, you may use a different system to classify gear oils. The ISO Viscosity grade system is used internationally, but the AGMA (American Gear Manufacturer’s Association) system is used in the Americas and some parts of Asia. A chart can be used to move that across these grading systems, as shown below in Figure 5.

As per (Sander, 2020), the AGMA numbers have some particular meanings as stated:

- No additional letters (only a number) – Contains only R&O additives

- EP – Mineral oil with Extreme Pressure additives

- S – Synthetic gear oil

- Comp – Compounded gear oil (3-10% fatty or synthetic fatty oils)

- R – Residual compounds called diluent solvents which reduce the viscosity to make it easier to apply

Another rating that is seen a lot is the CLP rating. This is a German oil standard defined by ASTM DIN 51517-3, in which the test requirements to meet the CLP specification are documented.

This DIN standard covers petroleum-based gear lubricants with additives designed to improve rust protection, oxidation resistance, and EP protection. Some typical classifications seen are CLP-M (which represents mineral gear oil), CLP HC (which represents synthetic oils [SHC, PAO, POE]), and CLP PG (which represents polyglycol PAGs), according to (Santora, 2018).

There are three main DIN 51517 classifications as per (Rensselar February 2013), namely;

- DIN 51517 CGLP – contains additives that protect from corrosion, oxidation, and wear at the mixed friction spots and additives that improve the characteristics of sliding surfaces

- DIN51517-3 CLP – contains additives that protect against corrosion, oxidation, and wear in the mixed friction zone

- DIN 51517-2 CL – contains additives that protect against corrosion and oxidation suitable for average load conditions

The above are some of the more prevalent naming systems for industrial gear oils, and they are found on most gear oils globally.

Find out more in the full article, "Gear Oil: Types, Applications, and Benefits" featured in Precision Lubrication Magazine by Sanya Mathura, CEO & Founder of Strategic Reliability Solutions Ltd.