What Baselines should you use?

Global oil suppliers have baseline or tolerance limits that are used when providing guidelines to customers about their equipment. The limits for a gearbox will differ from those of an engine. For instance, an iron content level of 3000ppm is normal for an automatic transmission gearbox but highly irregular for a diesel engine! Hence, it is important to know the limits associated with the application.

Some labs have also developed their own set of limits based on years of collecting hundreds of samples and liaising with their customers in the field. OEMs have also developed their own sets of limits (usually displayed in their manuals) based on their testing in the lab and on the field.

Knowing your own “normal” is more valuable than any generic industry limit.

Ideally, when developing your target levels, you should trend your data and find out what “normal” looks like for your equipment. In some cases, what is normal for your environment may be abnormal in a different environment. But it is important to note when normal varies from standard operating tolerances. This is where you would want to work together with your oil supplier, lab, and OEM to develop tolerances that align with your equipment.

Depending on your maintenance program, you can also adjust the tolerance accordingly. If you are aware that maintenance may not act on a threshold limit right away, it may be a good idea to add some padding to those limits. This ensures that the equipment does not suffer by pushing it to the limits.

What are the Oil Analysis Limits for Diesel Fleets?

Let’s explore how to set the limits for a diesel engine fleet of trucks.

Here is a step by step guide on developing an oil analysis program for diesel fleets.

First, let’s categorize the trucks into critical, semi-critical, and non-critical.

The critical ones are those that, if they break down, there is no replacement; the downtime hurts us financially and can delay the project. These need to be available 24/7.

The semi-critical ones are those that still have an impact on the operation if they break down, but it’s not quite as disastrous. These can be trucks that are not on tight deadlines, can afford to have some leniency or delays with their workload.

The non-critical trucks are those that can be easily swapped out for another truck without causing any delay or impact to the project, but they are still important.

Now that these are categorized, we need to find out what types of engines are being used and what the recommended diesel engine oils are for these units. Typically, most operators have mixed fleets. Thus, one may see a wide age/mileage gap in the engines. This gives us an idea of the reliability of the engines, which can impact the setting of the tolerance limits.

Since it’s a diesel engine fleet, it would be worthwhile to consider the type of fuel being used for this fleet. With diesel engines, there are varying levels of sulphur in the fuel, which can impact the oil drain intervals as well.

For this fleet, we may need to establish varying oil drain intervals to ensure maximum reliability, based on the categories outlined by their criticality. Before adopting set oil drain intervals, it is important to execute a pilot project with the fleet to anticipate any rollout challenges for the future. We will discuss these in more detail in the case study section.

Real-World Results from a Diesel Fleet Oil Analysis Program

Fleet: Mixed long-haul trucks of various ages/mileages

Predominant oil: Mineral 15w40 Diesel engine oil (CI4 spec)

Regular Oil Drain Interval: 3000km (based on best practice over time)

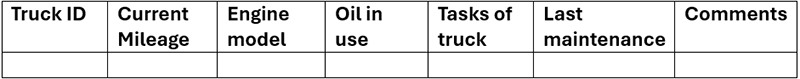

Approach: An engine asset list was first compiled for every truck in the fleet. This follows the table below:

It’s important to have a column for comments as this can capture some data that we may not be aware of, such as a recent engine overhaul done to the unit, or the driver has regularly lost power over the past few weeks, or the driver tops up the oil every time he gets back to the yard.

These little details may not be captured in the CMMS (if one exists) or the maintenance logs, but they are crucial in determining whether we can safely extend the oil drain intervals or not. For units that require special attention or are under warranty, these may have to be excluded until more favorable conditions exist.

Based on the fleet (15 trucks), they were categorized into three main groups:

Critical – these units were being used every day on projects that had tight deadlines. They were often unavailable to return to the yard for maintenance or oil changes, as each hour away from the job affected the project deadline.

Semi-critical – these units were utilized by various customers at distant locations and often spent most of their time at the customer site (due to the distance). Hence, basic maintenance was usually performed at the customer’s site, causing minimal disruption to the operation.

Non-Critical – these units are often deployed in situations where extra assistance is required, or they are the standby units if one of the critical units is in trouble.

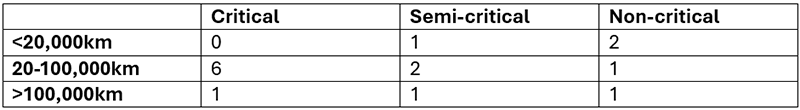

Even though they had these three groupings, the engine types and mileages were very varied. Hence, a matrix was formed for this fleet.

The majority of the fleet falls within the 20-100,000km range, spanning across the critical, semi-critical, and non-critical categories.

A pilot test was done on the following:

- 3 of the critical units within the 20-100,000km range

- 1 semi-critical unit in the >100,000km range

- 1 non-critical unit in the > 100,000km range

Since the typical oil drain interval was 3,000km, we took samples at 1500, 2000, 2500, and then again at 3000km. Based on the trend observed from the first 3 samples, we had a fair indication of the condition of the oil before it got to 3000km.

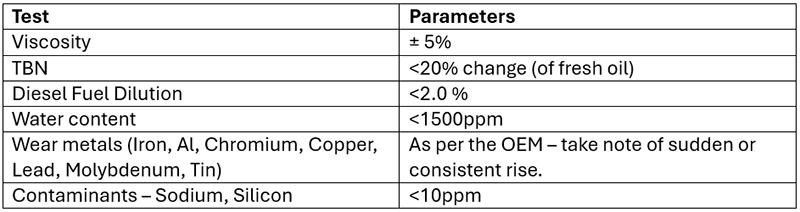

None of the samples showed any unusual signs of wear, excessive additive depletion, or ingress of contaminants. For these samples, we kept a close eye on maintaining the following parameters:

Samples were then taken at 3500, 4000, 4500, 5000, 5500 & 6000km. Then, another set of samples was taken at 6500, 7000, 7500, and 8000km once the oil analysis values were still within range. The aim was to at least double the oil drain interval for this fleet.

Intervals of 500km were used as a cautionary value to allow enough time for any anomalies to be caught. The critical engines got to these values faster than the semi-critical and non-critical units.

All of the critical units easily got to 9000km without any of the oil analysis values entering the warning zones. However, the semi-critical unit, which had exceeded 100,000km, only made it to 8,500 km before the TBN and fuel dilution values entered the warning zone. The non-critical unit, which exceeded 100,000km, also reached 9,000 km without any issues.

Since the owner wanted to be on the side of caution (and allow some wiggle room between the intervals for trucks which could not get maintenance done at the specified interval), they chose to change the oils across the fleet at the 7500km mark but keep the oil analysis program where they perform samples at 4000 & 7000km.

They will now work alongside oil analysis, and for some trucks, where they believe they can have an even longer interval, they will extend it accordingly.

What does this mean?

These engines take approximately 44 quarts or roughly 42 liters of oil and are changed every 3000km or roughly 2 months (critical units) with an average of 3 hours downtime for the oil change.

Hence, one unit undergoes approximately six oil changes per year:

- An average of about 3 hours x 6 times = 18 hours downtime

- An average of 42 liters x 6 times = 252 liters changed per year

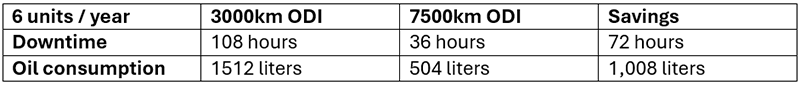

- Thus, for six critical units that would be:

- Downtime => 18 hours x 6 units = 108 hours

- Oil consumption = 252 liters x 6 units = 1,512 liters

The new oil drain interval of 7500km resulted in a 2.5-fold increase in the interval.

This means that the new interval would be every 5 months instead of every 2 months.

Thus, these six units would only do oil changes twice for the year.

New downtime = 3 hours x 2 times/year x 6 units = 36 hours / year

New oil consumption = 42 liters x 2 times/year x 6 units = 504 liters

The following table summarizes the changes.

This is just for part of the fleet, and a dollar value has not been assigned to these, but clearly, there are lots of benefits to extending the oil drain interval through guided oil analysis.

Find out more in the full article, "How to extend oil Drain Intervals Safely using Condition Monitoring" featured in Precision Lubrication Magazine by Sanya Mathura, CEO & Founder of Strategic Reliability Solutions Ltd.