Have you ever received your bloodwork results from your doctor, only to be more confused than ever? With all the long names and numbers just sitting on the piece of paper, Google (or ChatGPT) becomes your best friend to help interpret what they mean. However, even with these tools of reason, there is usually a disclaimer that states, “Please consult your doctor for a more accurate interpretation”.

Numbers alone don’t tell the whole story – context is what makes oil analysis meaningful.

One of the reasons for constantly looping your doctor back into the mix is that they have your history, they know how your body responds to certain things, and values which may get flagged because they are outside of the limits may be waived away by your doctor because it is normal for your body based on your history and DNA.

The same applies to oil analysis. Depending on the application and operating environment, certain conditions may be met that can be interpreted as unusual. Still, if you’re familiar with your system, you will understand the reason behind the numbers.

Viscosity

As mentioned earlier, viscosity is the most important characteristic of a lubricant. If it is too thick for the application, this can lead to efficiency loss, increased heating, and a slowdown of the system. Essentially, a significant amount of work needs to be done on the oil to make it compatible with the application.

On the other hand, if it is too thin, then we run the risk of improper lubrication. Therefore, we increase the chances of wear occurring in the applications.

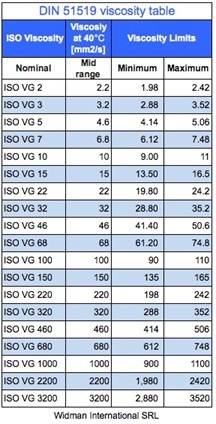

Viscosity is usually measured at either 40°C (for industrial applications) or 100°C (for engine applications). However, most labs put a ±5% tolerance limit for many oils. But why use such a random figure? The DIN 51519 table is used to determine ISO viscosity, with each value within a 10% range, as shown in Figure 1.

When you see an ISO VG 100 oil, the chances are that the actual viscosity of that oil varies between 90-110cSt. Therefore, if we start seeing our results vary by around 5% or trend towards the outer limits of any viscosity class, we know that something is going on with our oil.

Presence of Wear Metals

Wear metals prove that some type of wear is occurring. However, depending on their quantity, they can also provide some more insights into what is actually wearing away and whether it is normal wear or abnormal wear. Wear is reported in parts per million (ppm) or as a percentage. Here’s how to convert those percentages to ppm:

100% = 1,000,000ppm

1% = 10,000ppm

0.1% = 1,000ppm

The most common wear metals tested include Aluminum, Iron, Chromium, Copper, Lead, and Tin. Depending on the application, there are varying levels at which these will be flagged.

Table 1 provides an example of various applications and their respective limitations. These will vary based on your OEM and environment, but can be used as a general guideline. All numbers in Table 1 are in ppm.

AN/BN and the Presence of Contaminants

Contaminants are any foreign material in the system. Sometimes, lab tests may not be able to detect contaminants in a system because they are not specifically designed to identify that particular contaminant.

In these cases, users would need to specify what additional contaminants the lab should look for, or perform a broader FTIR (Fourier Transform Infrared) analysis to identify all the components in the oil and then determine which of them are contaminants.

The most common contaminants tested include Silicon, Water, and Fuel. Although AN/BN (Acid Number and Base Number) may not be considered a contaminant, it helps quantify the acid in your system, which shouldn’t be there; therefore, in some ways, it can be viewed as a contaminant. However, it is primarily a physical property and is listed separately.

Acid and base numbers act like an early warning system for oil health.

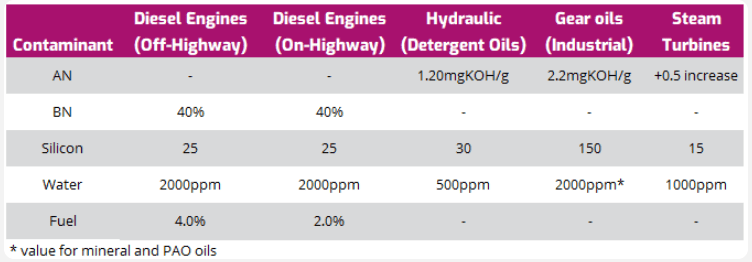

For diesel engines, BN is measured as having high base numbers, which will decline over time as acids accumulate. If the BN value declines to around 50% of its original value, then we have an issue with the acids increasing too quickly in the oils. On the other hand, AN is used for all other industrial oils (gears, hydraulics, etc.). There are varying limits for AN depending on the application, as shown in Table 2.

Silicon usually indicates the presence of sand, which is highly abrasive. This can accelerate wear in any equipment by essentially turning the oil into sandpaper and wearing away the insides of the equipment. Some of its limits are shown in Table 2.

Water in any form is highly destructive to all assets. However, some systems can tolerate a bit more water than others. This can be due to the nature of the oils (good demulsibility) or the nature of the systems, where heat is involved to help remove the water. Water in the system can lead to an increase in viscosity and disrupt the oil layer.

As such, the lubricant will not be able to form a full film to protect the asset. Water can also create an emulsion in the oil or lead to corrosivity issues. Table 2 gives some examples of limits for various systems.

Fuel contamination is an issue for most diesel engines. The presence of fuel in your oil can lead to a lower viscosity (hence the oil can no longer protect the components) and an increase in the flash/fire point of the oil, which can be particularly dangerous. We have some limits noted in Table 2.

Presence of Additives

It is more challenging to place these tests in a one-size-fits-all table, as oil formulations are consistently changing. The best way to interpret these additives would be to compare them against the initial values for the finished lubricant.

For your oil analysis program, always have a representative sample of the new oil so that comparisons can be made against it as the oil ages in the system. Additionally, the presence of additives in your report when they shouldn’t be there is also a sign of contamination, likely with another type of oil.

Find out more in the full article, "How to Read Oil Analysis Reports and translate Data into Reliability" featured in Reliable Magazine by Sanya Mathura, CEO & Founder of Strategic Reliability Solutions Ltd.