For industrial refrigeration systems, there are a couple of essential pieces of information to consider before selecting the most suitable oil. The user must know the refrigerant in use, the evaporator type (dry or wet; carryover < 15%), the evaporator temperature, the compressor type, and the outlet temperature.

The refrigerant fluids are classified as per the ASHRAE classification (ANSI-ASHRAE Standard 34-2001):

- R717 — Ammonia

- R12 — Chlorofluorocarbon (CFC)

- R22 — Hydrochlorofluorocarbon (HCFC)

- R600a — Isobutane

- R744 — Carbon dioxide (CO2)

- R134a, R404a, R507 — Hydrofluorocarbons (HFC)

It should be noted that CFCs were banned under the Montreal Protocol (1989) due to their Ozone Depletion Potential, and HCFCs are being phased out due to their Global Warming Potential.

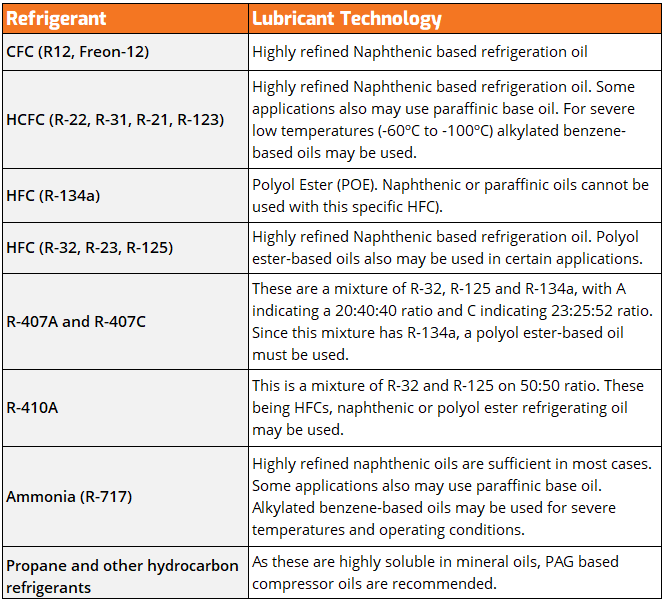

Chevron provides some general guidelines for selecting the appropriate refrigerant, as shown in the table below.5

(But you should always follow the guidelines of your OEM when selecting the appropriate lubricant.)

ExxonMobil classifies its refrigeration lubricants based on refrigerant type, evaporator temperature, and compressor type (Piston, Screw, or Centrifugal). This is very helpful when determining the best-suited lubricant for your refrigerant compressor.

Find out more in the full article, "Compressor Oil, Types, Applications and Performance Drivers" featured in Precision Lubrication Magazine by Sanya Mathura, CEO & Founder of Strategic Reliability Solutions Ltd.