“When should an oil sample really be taken?”

In used oil analysis, oil samples can be taken at any time, but one should always consider the insight that they are trying to gain before testing the sample. This is crucial in deciding the type of tests and the intervals at which they should be performed.

For instance, if we are testing the quality of the oil or we want to compare a fresh batch to a used one, then we can take a sample directly from the drum.

If we are trying to decide the rate at which the additives are being depleted or wear being accumulated then we can take a sample at different operating hours to trend the data. This method can work if we are trying to determine the most appropriate run time for a lubricant in particular conditions.

However, if we are trying to track the health of the components on a regular basis as part of our PM program then taking a sample at the end of the scheduled maintenance interval is desired.

Taking an oil sample from a component is like performing a blood test by the doctor. It helps us to understand what’s really happening. It can show us if there is excessive wear, contamination or lubricant degradation which allows us to identify its “health”. However, the correct tests need to be carried out to determine these conditions.

There must be a reason behind taking the oil sample, not just a random act. When trying to establish a trend regarding a particular aspect of the oil, this should guide your choice of tests otherwise we can end up paying for tests that do not add value.

Always ensure sound reasoning behind testing rather than just checking the box!

While taking an oil sample at the end of the scheduled operating hours is very convenient, is it truly efficient?

When a piece of equipment is scheduled for maintenance, it is usually taken out of service for a couple of hours to perform the assigned

maintenance tasks.

However, if an oil sample is taken a couple days in advance of the scheduled maintenance, then when the results return the maintenance team can be on the lookout for issues highlighted by the results.

For instance, if the value for iron was significant or rising then they can perform inspections for areas which may cause this type of wear and address this challenge while the equipment is offline.

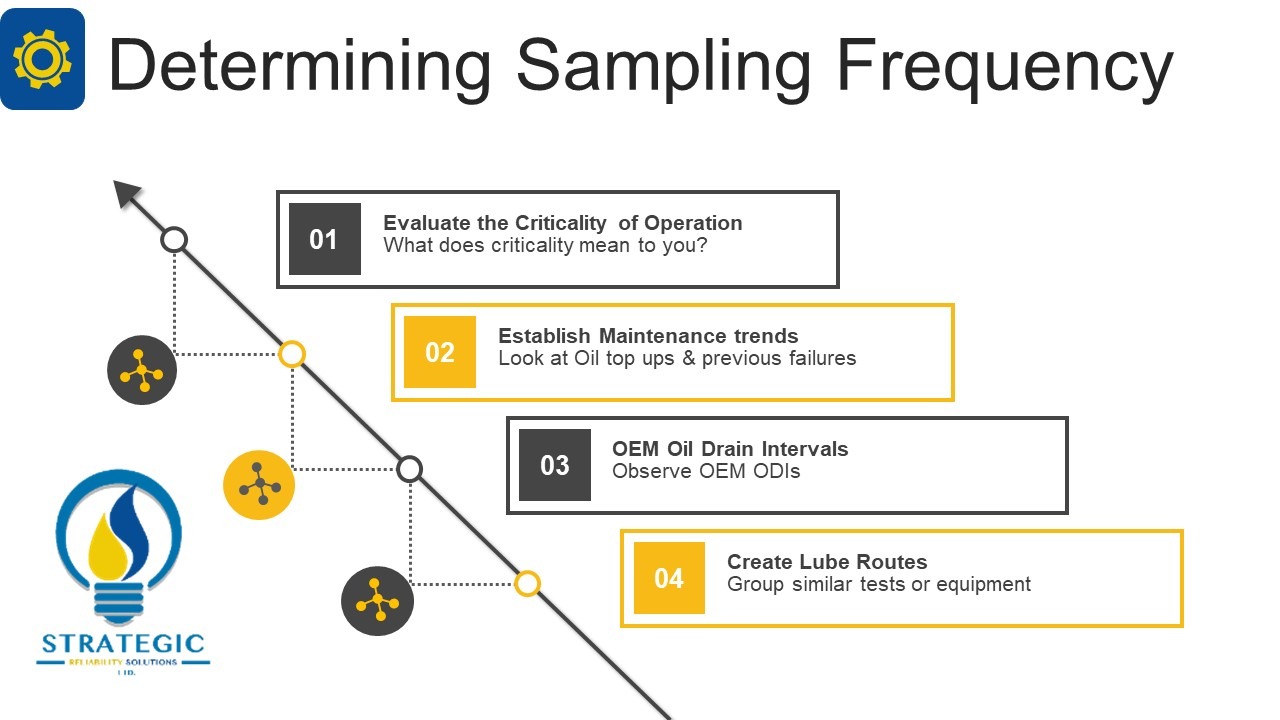

The graphic on the side can be used as a quick guide to determining when to take a sample.

Remember to always evaluate the reason behind establishing the sampling frequency before scheduling sampling.