Compressors are integral to many of our operations. They are used to compress gas, increasing its pressure, and to power tools. They can also be used as vacuum pumps or blowers, but each application is different. As such, they require various types of lubrication, particularly for applications that use specific refrigerants and come into contact with the lubricant.

In all these applications, the functions of the oil remain largely the same: it must lubricate the surfaces, prevent wear and corrosion, maintain the required viscosity, and provide proper sealing.

In this article, we will dive into the various types of compressor oils and explain why they are suited to these applications. We will also discuss monitoring the health of these oils and the tests that should be performed to ensure your compressor oils remain healthy.

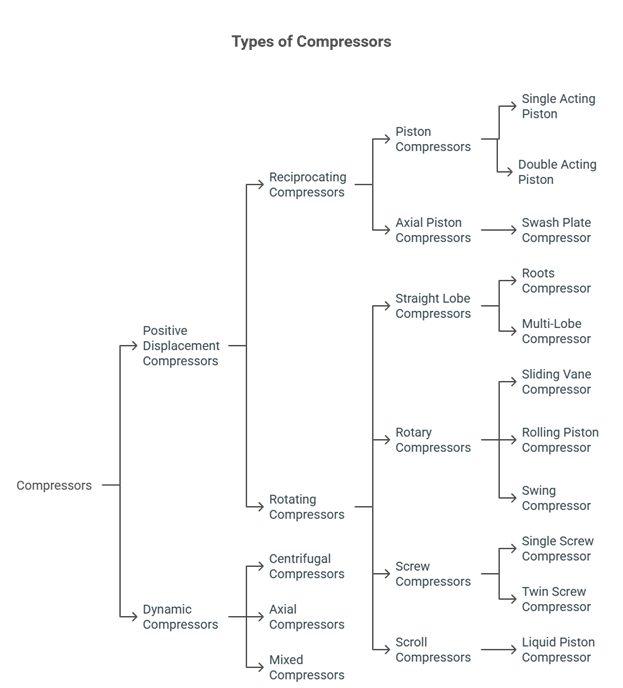

Types of Compressors

Essentially, there are two main types of compressors: Displacement and Dynamic. For displacement compressors, gas is drawn into a chamber, compressed, and expelled by a reciprocating piston. On the other hand, for dynamic compressors, turbine wheels accelerate a medium, which is then abruptly accelerated.1

Positive displacement compressors include Reciprocating and Rotating compressors. These can be further subdivided as shown in Figure 1. For Dynamic (Turbo) compressors, these are further subdivided into Centrifugal, Axial, and Mixed types (also shown in Figure 1).

Depending on the type of compressor, the required lubricant will vary. For example, positive-displacement compressors use rolling or sliding motion and include bearing and sealing components within the compression chamber. On the other hand, dynamic compressors use hydrodynamic journal and thrust bearings, or rolling-element bearings, to support the main shaft, which is isolated from the compression chamber.

Working pressures, temperatures, and the type of gas being compressed also play a significant role in determining the appropriate lubricant.2

As with most applications, there can be a dry-sump or a wet-sump. Wet sumps are typically seen in reciprocating and rotary screw compressors. In a wet sump, the gas usually contacts the oil, lowering its viscosity. This is where it is essential to note the gas’s solubility in the system oil. Natural gas and other hydrocarbons are more soluble in mineral oils and PAOs than in PAGs and diesters. Thus, PAGs may be preferred in some cases to avoid lubricant failure.

Compressor Oils

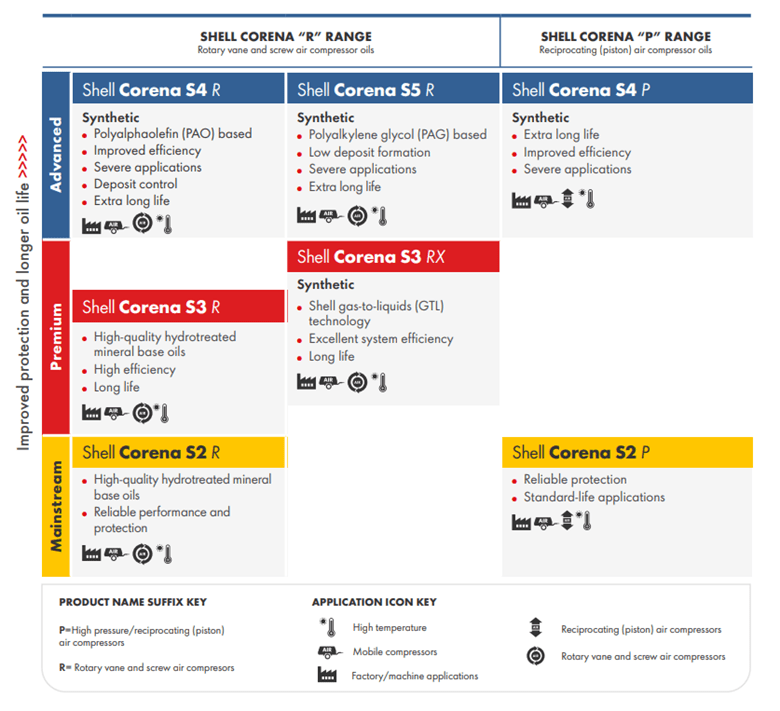

Most of the major global lubricant OEMs have classified their oils based on:

- Rotary vane and screw air compressor oils

- Reciprocating (piston) air compressor oils

- Refrigeration compressor oils

As seen below in Figure 2, Shell Lubricants3 has a line of lubricants, particularly for air compressors, which are further classified into mineral oils, PAOs, and PAGs for Rotary vane and screw air compressors or Reciprocating (piston) air compressors.

In reciprocating air compressors, cylinder design dictates the lubrication type, as this is the most severe application. Compressing the gas usually results in high temperatures, which can easily lead to oxidation. The compressed gas must be free of contaminants, as contaminants can accelerate oxidation. Typically, for reciprocating air compressors, mineral oils or PAO- or di-ester-based lubricants in the ISO VG 68 to 150 range are preferred.

Rotary vane compressors can experience pressure extremes as the vanes slide to compress the gas, and oil is continuously injected into the compressor chambers. Typically, ISO VG 68-150 oils are used in this application.

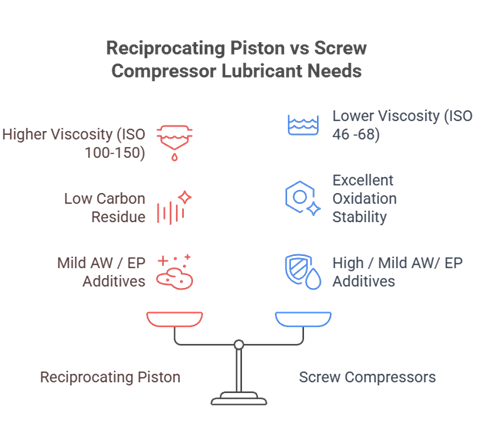

For screw compressors, the oil must perform several functions, including lubricating the meshing rotors and the plain and roller bearings that form part of the geared coupling. ISO VG 46 mineral oils are usually used in these compressors, but the viscosity can be increased to ISO VG 68 or to synthetic PAO or PAG lubricants at higher ambient temperatures. Similarly, Group III base oils of these viscosities can be used in this area. Most screw compressor oils contain mild EP/AW performance additives and require an FZG failure load≥10.

Ideally, reciprocating piston compressors will use higher viscosities (ISO VG 100-150) with extremely low carbon residue and no or mild EP/AW additives. Conversely, screw compressors will use lower viscosities (ISO VG 46 or 68) with excellent oxidation stability and mild/high AW/EP additives1, as shown in Figure 3.

Find out more in the full article, "Compressor Oil, Types, Applications and Performance Drivers" featured in Precision Lubrication Magazine by Sanya Mathura, CEO & Founder of Strategic Reliability Solutions Ltd.