Varnish is a type of deposit that forms on the surface of equipment in lubrication systems. It is caused by the oxidation of the base oil and the buildup of additives in the oil over time, forming a sticky, varnish-like substance. Lube oil varnish can cause problems in equipment operation by clogging filters, reducing oil flow, and leading to valve sticking and pump failures.

Lube oil varnish is no stranger to the manufacturing industry. It constitutes the substance of most operators’ worst nightmares and plant managers’ ultimate fears. For those who have been in the industry for the last decade, varnish is the sticky subject that unites all facility departments.

It can cause an entire manufacturing plant to shut down while sending the finance department into a frenzy trying to balance production loss with incoming repair costs. In the fight against lube oil varnish, all teams need to work together to ensure that it can be managed and possibly eliminated from the system.

What Is Oil Degradation?

Before diving into the world of varnish, one must first understand how it forms and the circumstances which have led to its existence. Within the industry, the term varnish is used loosely to define any form of lubricant-derived deposit found in industrial.

However, oil can degrade by several mechanisms, which require various conditions for degradation—as such, using the term varnish to describe any deposit formed within a machine does not suggest its mechanism of formation.

The lubricant begins its degradation journey from the moment the lubricant enters the machine.

A lubricant is composed of base oil and additives, of which infinite combinations exist. Additives are carefully engineered to protect the base oil and the equipment. As such, they can become depleted over time, leading to the degradation of the lubricant.

This becomes concerning when the additive levels have depleted to a threshold where they can no longer protect the base oil or the machine. At this stage, degradation is the most serious concern because its rate is greatly accelerated.

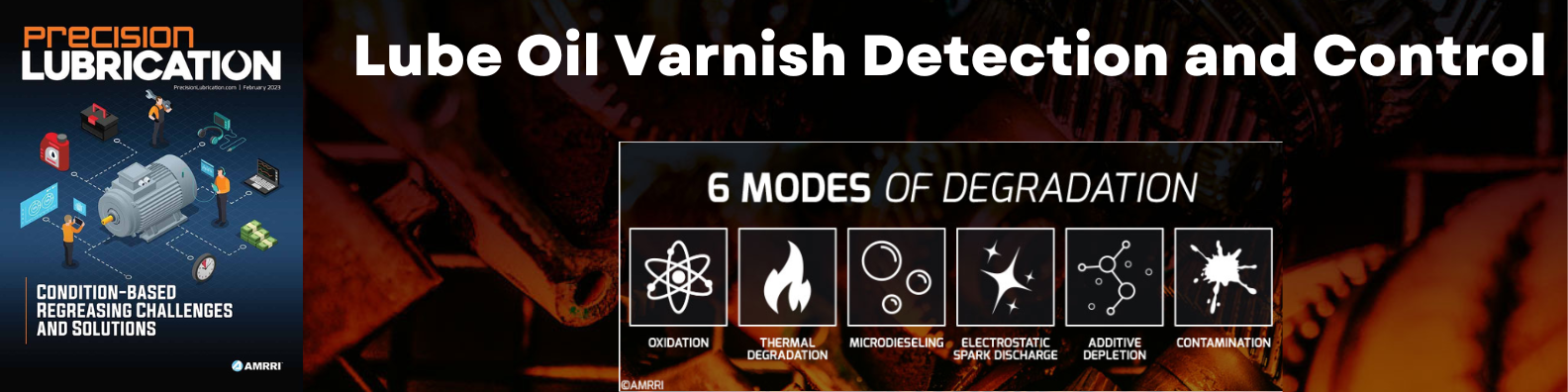

According to Mathura (2020), there are six major forms of degradation under which a lubricant can undergo. While some may argue that these can be grouped, some characteristics set these mechanisms apart.

Each mechanism has unique environmental factors which contribute to producing different types of deposits. It is critical to note that identification of the type of mechanism can assist operators in performing remedial works on their equipment to aid in preventing the formation of varnish.

Want to read the full article? Check it out here in the Precision Lubrication Magazine.